Message

The many components we handle are small enough to fit in the palm of one's hand. Each of these small parts are indispensable for the proper functioning of large aircraft and industrial machinery. They play a crucial role in supporting the infrastructure of society, and we take pride in producing such components.

Being a precision parts manufacturing company comes with significant responsibility. This includes advancing the precision machining techniques cultivated over our long history and being committed to quality and personnel development for the future. We strive to respond to the changing needs of the times and contribute to society.

Our business has thrived for more than 80 years, and this longevity is owed to the support of our business partners, financial institutions, employees, and the entire community. We truly appreciate your continued support.

Nobuhiro Hasegawa

Representative Director

About

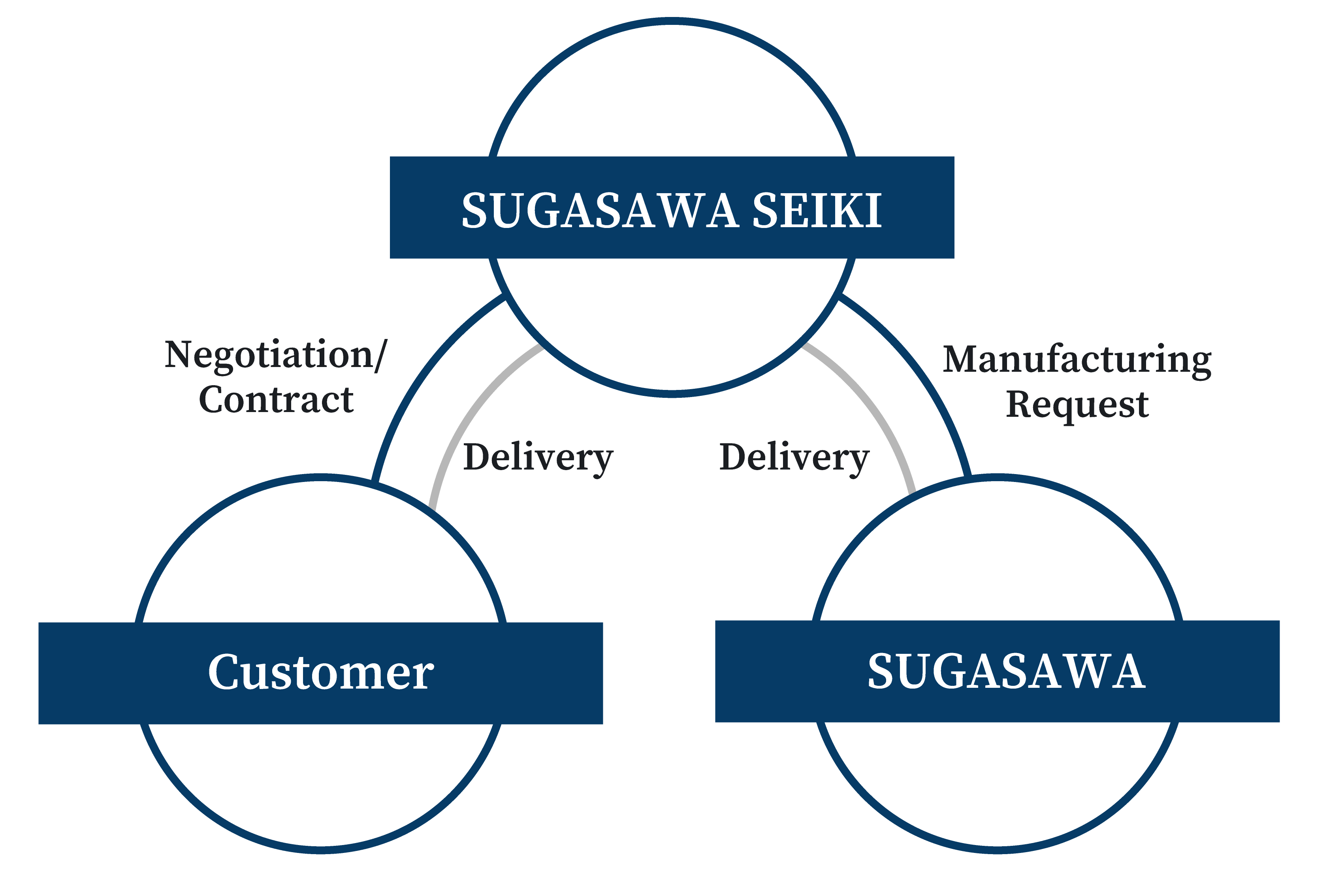

SUGASAWA SEIKI manages customer interactions and sales. We conduct proposal-based sales, using our expertise in precision machining in response to inquiries.

We actively engage with customers from the design stage, proposing ways to reduce costs and improve the product. We aim to exceed customer expectations and create parts that have increased accuracy and performance. The same specifications presented to SUGASAWA SEIKI will yeild a superior product. Our approach has earned us high praise, leading to the adoption of our products for government agencies.

Not limited to Japan, we actively pursue direct transactions with overseas companies, contributing to Japan's technological prowess from a global perspective.

Company Information

| Company Name | Sugasawa Seiki Co., Ltd. |

| Representative Director | Nobuhiro Hasegawa |

| Address | 10-6 Ichiba Yamatocho, Tsurumi-ku, Yokohama, 230-0025, Japan |

| Phone Number | +81-45-521-9826 |

| Established | February 11, 1939 |

| Capital | 10 million yen |

| Site Area | 893 square meters |

| Building Area | 428 square meters |

| Main Products | Machinery components, Hydraulic equipment, Diesel engine fuel injection parts, Aircraft components |

| Major Customers | MITSUBISHI HEAVY INDUSTRIES, LTD., Toshiba Corporation, SHIMADZU CORPORATION, MOOG Inc. |

Relations

SUGASAWA SEIKI is responsible for sales, conducting proposals in response to customer inquiries. The manufacturing tasks resulting from your orders are carried out by the SUGASAWA.

By consolidating functions within each company, we aim to enhance productivity while collaborating between the two entities to deliver precision machining that exceeds customer expectations.

History

| February 1939 | Toshizo Hasegawa founded SUGASAWA SEIKISHO in Yokohama City. |

| August 1945 | Moved to Yamato, Yokohama City and started manufacturing construction vehicle parts. |

| October 1953 | Renamed the company to SUGASAWA SEIKI and appointed Toshishiro Hasegawa as Executive President. |

| May 1961 | Established SUGASAWA SEIKI factory in Kawasaki City as the hydraulic equipment division. |

| August 1967 | Established SUGASAWA SEIKI factory in Yokohama City. |

| May 1969 | Separated SUGASAWA SEIKI Kawasaki Factory and established SUGASAWA HYDRAULIC in a joint venture with Tokyo Keiki Co., Ltd. |

| August 1971 | Established SUGASAWA SEIKI factory in Oe, Yamagata Prefecture. |

| April 1978 | SUGASAWA SEIKI became a certified Caterpillar factory of the Mitsubishi Corporation. |

| April 1981 | Moved SUGASAWA SEIKI's headquarters to Yokohama City. |

| May 1981 | The Oe factory was separated from SUGASAWA SEIKI and established SUGASAWA. |

| April 1983 | The SUGASAWA Sagae Factory was built in the Chuokougyodanchi in Sagae City. |

| November 1987 | Moved SUGASAWA's headquarters to Sagae City, Yamagata Prefecture. |

| November 1988 | SUGASAWA SEIKI became a certified certified supplier by Caterpillar Inc., USA. |

| July 1995 | Established a new factory for SUGASAWA in Sagae City, Yamagata Prefecture, and relocated the headquarters. |

| July 2000 | SUGASAWA SEIKI and SUGASAWA obtained ISO9002 certification. |

| August 2003 | SUGASAWA SEIKI and SUGASAWA obtained QS9000 certification. |

| April 2004 | Moved SUGASAWA SEIKI's headquarters to Yokohama City. |

| July 2006 | SUGASAWA SEIKI and SUGASAWA obtained ISO9001 certification (based on TS16949). |

| September 2006 | Merged SUGASAWA HYDRAULIC into SUGASAWA. |

| August 2011 | SUGASAWA SEIKI and SUGASAWA obtained AS9100 certification. |

| August 2016 | SUGASAWA SEIKI and SUGASAWA obtained ISO 22301 (BCMS) certification. |

| August 2017 | SUGASAWA obtained Nadcap (NDT: MT) certification. |

Access

10-6 Ichiba Yamatocho, Tsurumi-ku, Yokohama, 230-0025, Japan

TEL:+81-45-521-9826

Nearest Station: 5 minutes on foot from Tsurumi Ichiba on the Keihin Kyuko Line

Business

Forging Tomorrow's Manufacturing

Precision Empowering Progress

We primarily specialize in the manufacturing of precision machined parts for industrial large-scale engine components, hydraulic machinery parts, and aircraft components. We have facilities for the assembly and functional testing of machined parts, which has helped us to establish a comprehensive production system from acquiring material to special processes and inspections.

SUGASAWA's Business Activities

Works

We manufacture precision components that support critical infrastructure worldwide. This includes industrial engine parts, hydraulic equipment parts, and aircraft components.

Hydraulic Component (Sleeve: Door Actuator)

Designed for civilian aircraft.

It has a diameter clearance of 6µm.

Material: SUS440C (Hardened and tempered to HRc55-60).

Hydraulic Component (Sleeve: Door Actuator)

Designed for civilian aircraft.

It has a diameter clearance of 6µm.

Material: SUS440C (Hardened and tempered to HRc55-60).

Fuel Injection Component (Nozzle Holder)

Atomizes high-pressure fuel (150MPa) through barrels and plungers, and injects it into the cylinders of a diesel engine.

Body Material: SCM435 (Carburized and hardened to HB269-321).

Nozzle Tip: (High-frequency hardened to Hv550 or more).

Fuel Injection Component (Plunger, Barrel)

Similar to the above, this is an electronically controlled injector with integrated plunger pumps and nozzles.

Housing Material: SCM420H (Carburized and hardened to Hv550 or more).

Plunger Material: SUJ2 (Hardened and tempered to HRc59-65).

Hydraulic Component (Pressure Balance Valve)

A high-precision flow control valve that adjusts the flow of hydraulic pumps with high control accuracy.

Body Material: FCD550.

Spool Material: SKD11 (Hardened and tempered to HRc56 or more).

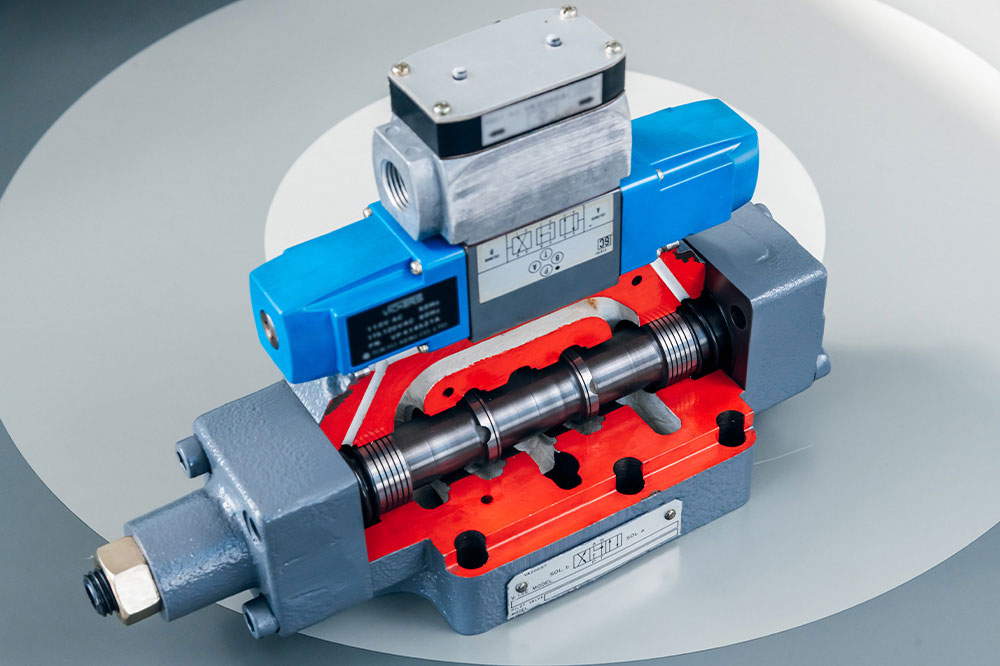

Hydraulic Component (Switching Valve)

An electromagnetic pilot switching valve. Used when there's a need to alleviate impact during switching, whether for high-flow or relatively low-flow applications.

Body Material: FCD450,500.

Spool Material: SCM415 (Carburized and hardened to HRa82-84).

Facility

We use specialized facilities, uncommon among other companies, to handle niche products with high-precision machining.

Our inspection facilities, are equipped with tools that allow for highly accurate inspections in line with advanced machining equipment. We conduct various inspections beyond surface precision, including special processes, to verify compliance with quality standards.

Quality

Commitment

We are dedicated to achieving the highest level in manufacturing by aiming for products with zero defects. We emphasize organizational management and quality management to ensure the safety of all our products. Especially in the case of aircraft components, even a single defect in quality could lead to serious accidents. Therefore, we are dedicated to the introduction of state-of-the-art inspection equipment and the preservation and cultivation of artisan skills in handling such equipment.

JIS Q 9100

JIS Q 9100 is a quality management system standard that is specific to the aerospace, defense, and aviation industries. It is equivalent to the American AS 9100 and European EN 9100 standards and is widely used as a global procurement standard for aerospace and defense industries.

This represents our commitment to quality, trust, and satisfaction.

Contact

After entering your inquiry details in the form below, please press the 'Submit' button.